PA 12 (Nylon)

The industry standard. Offers excellent strength, stiffness, and good chemical resistance. Ideal for a wide range of functional parts.

The ultimate solution for durable nylon parts with complex geometries and complete design freedom.

Selective Laser Sintering uses a high-power laser to fuse small particles of polymer powder. The laser selectively scans a cross-section of the design onto a bed of powder, sintering the material together. The platform then lowers, a new layer of powder is applied, and the process repeats. Unused powder supports the object during printing, eliminating the need for dedicated support structures.

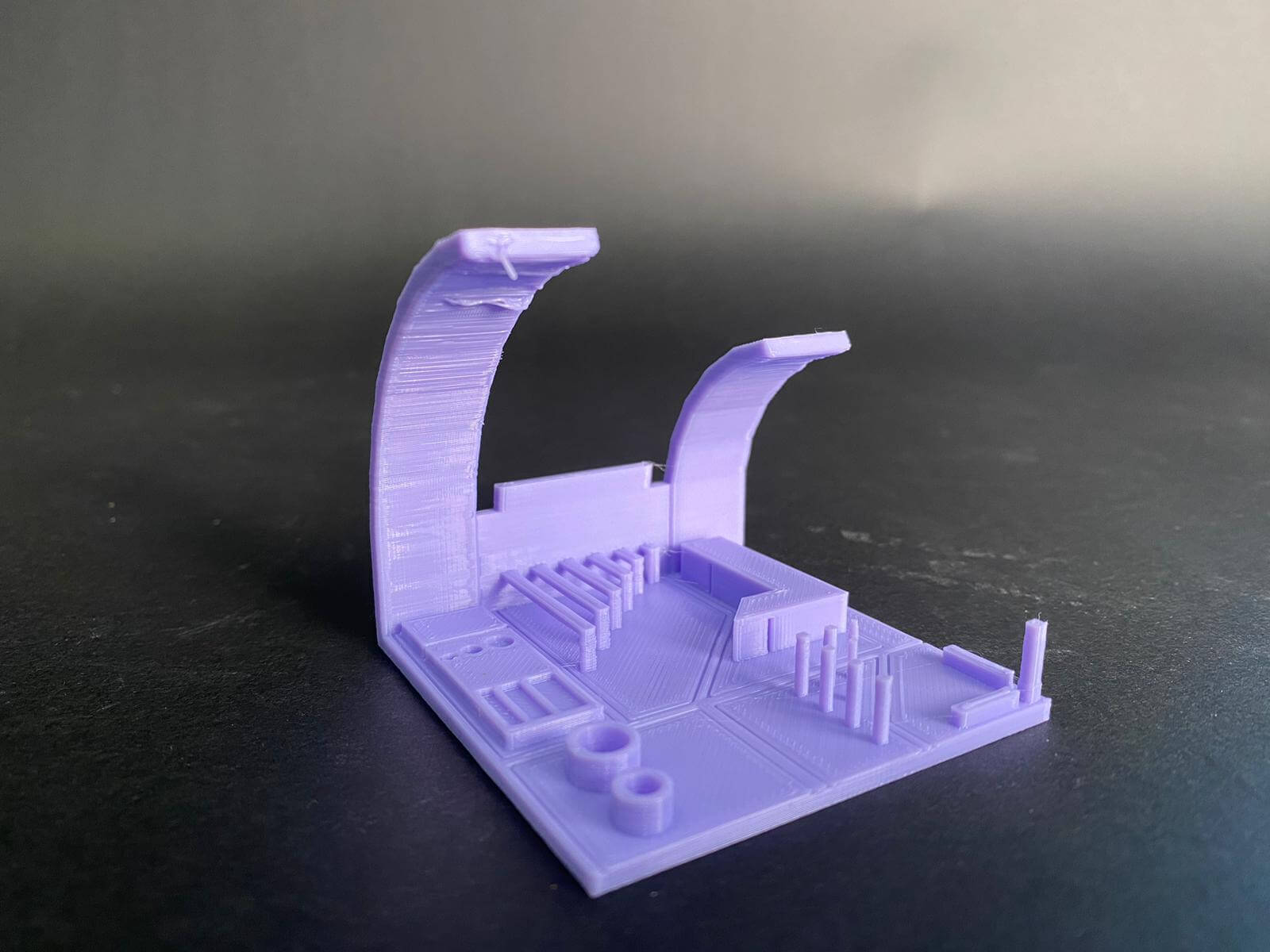

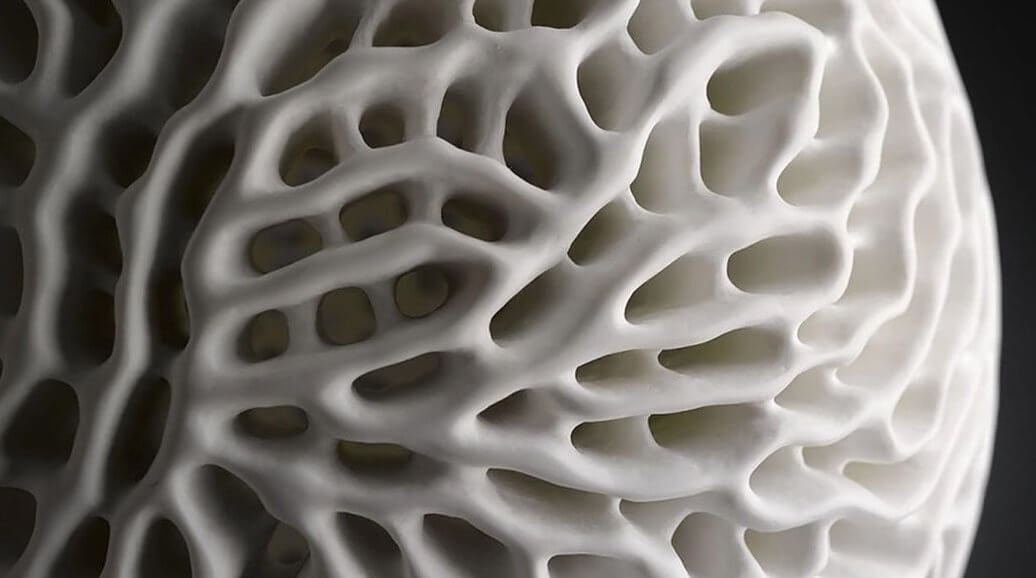

The self-supporting nature of the powder bed eliminates the need for support structures, allowing for intricate, complex, and interlocking parts.

SLS parts are known for their high strength, stiffness, and durability, making them suitable for demanding functional applications.

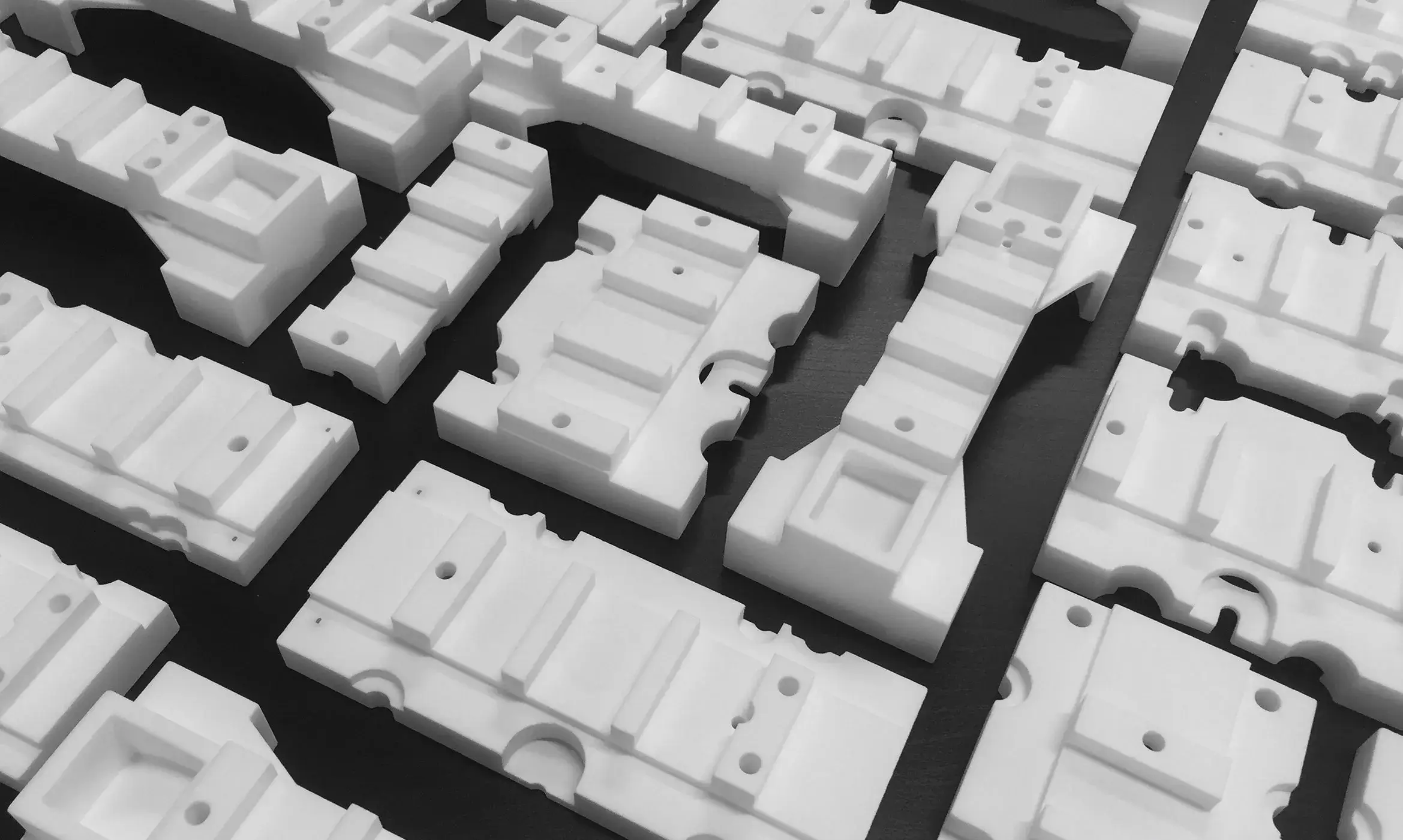

The ability to nest multiple parts within the build volume makes SLS an efficient and cost-effective choice for short-run manufacturing.

The industry standard. Offers excellent strength, stiffness, and good chemical resistance. Ideal for a wide range of functional parts.

More flexible and impact-resistant than PA 12. Excellent for parts that require high ductility, such as snap-fit components and living hinges.

Nylon filled with glass beads, offering higher stiffness, temperature resistance, and dimensional stability.

Carbon-fiber filled nylon for maximum stiffness and strength-to-weight ratio. Used for high-performance applications.

Create parts with intricate internal channels, lattices, and other geometries impossible with traditional manufacturing.

Efficiently produce batches of durable, end-use parts for short-run manufacturing and custom products.

Build robust prototypes that can withstand rigorous functional testing in real-world conditions.

Maximum Build Volume

300 x 300 x 580 mm

Standard Layer Height

100 - 120 microns

Dimensional Accuracy

± 0.3% (min ± 0.3 mm)

Create strong, complex, and functional parts without limitations. Get an instant quote for your SLS project today.

Start Your SLS Project