Standard Resin

Excellent for high-detail visual prototypes with a smooth surface finish.

Where immaculate detail and flawless surface finish bring your most intricate designs to life.

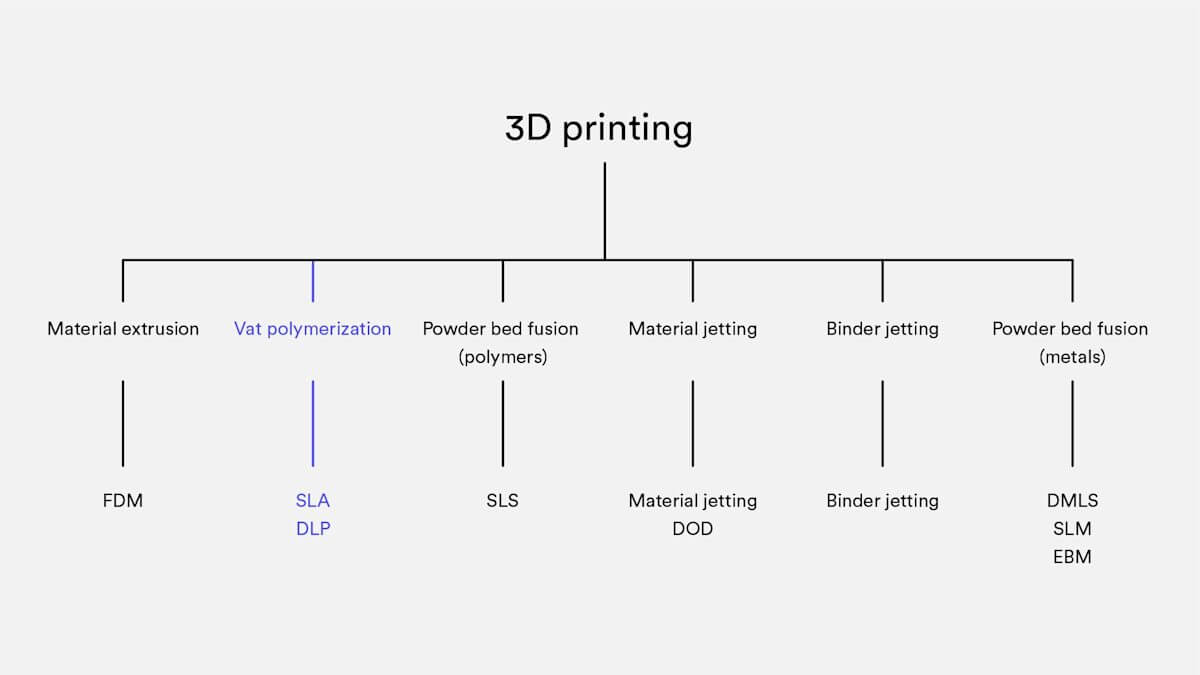

Stereolithography is an additive manufacturing process that uses a high-precision ultraviolet (UV) laser to selectively cure liquid photopolymer resin in a vat. The laser draws each layer of the design onto the resin's surface, solidifying it. The build platform then lowers, and the process repeats layer by layer until the final, highly detailed object is complete.

SLA is renowned for its ability to produce parts with extremely fine details, sharp edges, and intricate features.

The process creates parts with a surface quality that is comparable to traditional manufacturing methods like injection molding.

SLA offers a wide range of specialty resins, including clear, flexible, castable, and biocompatible options for specific needs.

Excellent for high-detail visual prototypes with a smooth surface finish.

Optically transparent material for fluidics, light pipes, and showcasing internal components.

Simulates ABS plastic, offering excellent strength and impact resistance for robust prototypes.

Simulates Polypropylene (PP), ideal for parts requiring high flexibility and low friction.

Simulates rubber-like materials, ideal for ergonomic parts, grips, and wearables.

Burns out cleanly with no ash or residue, perfect for creating patterns for investment casting.

Certified for medical and dental applications requiring skin or mucosal contact.

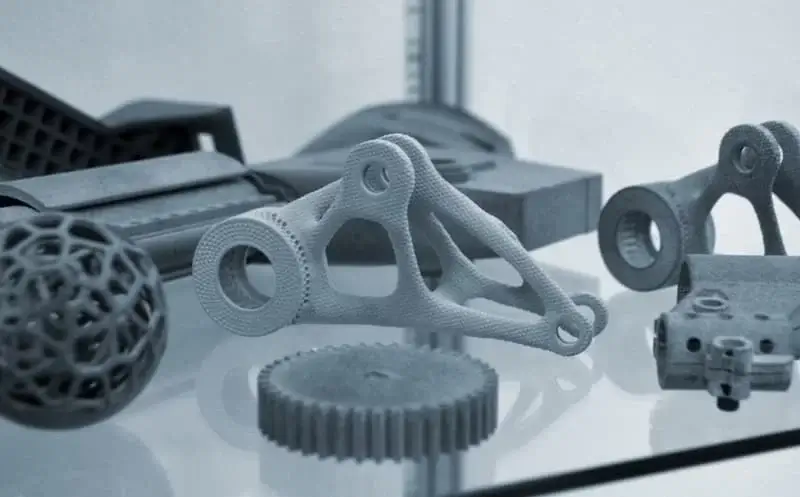

Create stunning, high-fidelity models for presentations, marketing, and form/fit testing.

Produce biocompatible surgical guides, dental models, and patient-specific anatomical models.

Fabricate intricate patterns for jewelry, metal miniatures, and other investment casting applications.

Maximum Build Volume

350 x 350 x 400 mm

Standard Layer Height

25 - 100 microns

Dimensional Accuracy

± 0.2% (min ± 0.1 mm)

Bring your most intricate designs to life with our high-precision SLA printing service. Upload your file for an instant quote.

Start Your SLA Project