PLA

Easy to print with great visual quality. Ideal for concept models and non-functional prototypes.

The intersection of strength, speed, and versatility for robust functional parts and rapid prototypes.

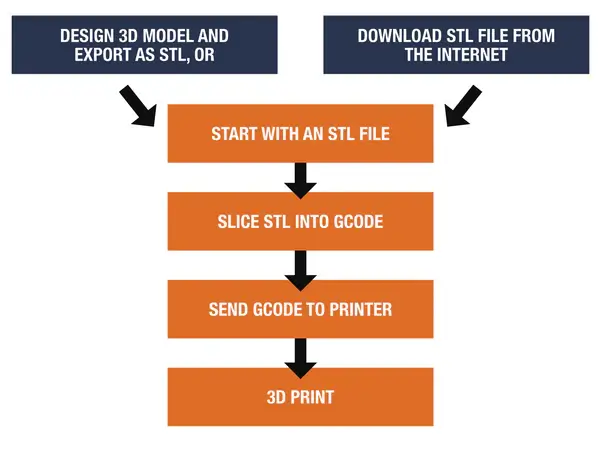

FDM is an additive manufacturing process that builds objects layer-by-layer by heating and extruding thermoplastic filament. A heated nozzle melts the material and deposits it on a build platform along a predetermined path. Each layer fuses to the one below it as it cools, creating a solid, durable object from a digital design.

FDM is one of the fastest and most affordable ways to produce prototypes and functional parts, enabling rapid design iteration.

Utilizing production-grade thermoplastics like ABS and ASA, FDM creates parts with excellent mechanical properties suitable for end-use applications.

From standard plastics like PLA and PETG to high-performance composites like Carbon Fiber Nylon, FDM offers a wide material library.

Easy to print with great visual quality. Ideal for concept models and non-functional prototypes.

Offers better strength and temperature resistance than PLA. Good for mechanical parts and food-safe applications.

High toughness, ductility, and temperature resistance. Used for functional prototypes and end-use parts.

Similar to ABS but with excellent UV resistance, making it perfect for outdoor applications.

Flexible, rubber-like material. Ideal for grips, seals, and parts requiring high impact absorption.

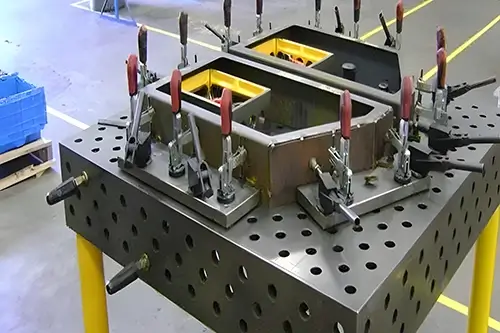

Exceptionally stiff and strong with a high strength-to-weight ratio. Used for jigs, fixtures, and lightweight tools.

Provides high levels of strength and heat resistance, suitable for a wide range of industrial applications.

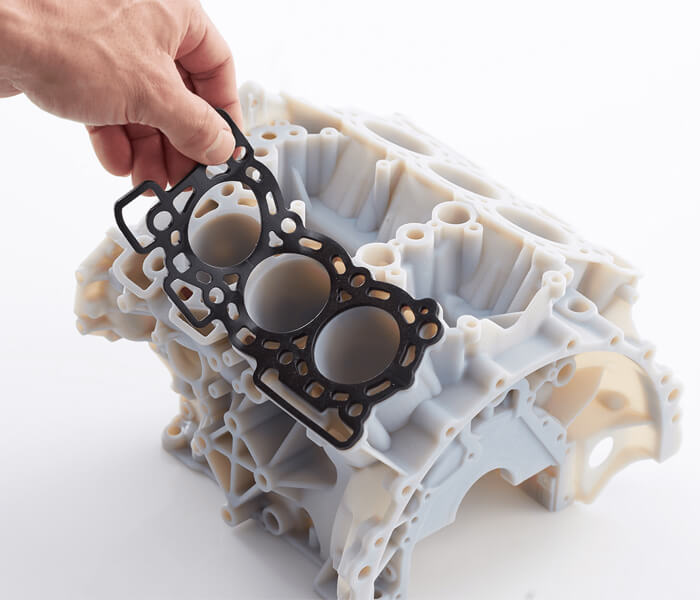

Quickly iterate and test designs with parts that mimic the mechanical properties of the final product.

Create custom, lightweight tools for assembly lines to improve manufacturing efficiency and ergonomics.

Produce low-volume production parts, custom enclosures, and components for specialized machinery.

Maximum Build Volume

600 x 600 x 600 mm

Standard Layer Height

100 - 300 microns

Dimensional Accuracy

± 0.5% (min ± 0.5 mm)

Upload your design file to our secure platform and receive an instant, competitive quote for your FDM project.

Start Your FDM Project